Horizontal Form Fill & Seal Machine

| Capacity | Up To 290 BPM |

| Bag Height | 35 – 250mm 1.4 – 9.9in |

| Bag Width | 60 – 450mm 2.4 – 17.7in |

| Bag Length | 20 – 120mm 0.8 – 4.7in |

Horizontal Form Fill & Seal Machine(HFFS) is suitable for pillow-type packaging of big products. Such as quick-frozen food with trays, biscuits, hamburgers, instant noodles, articles for daily use, drug sundries, and so on.

It is a heat-sealing pillow with double frequency, automatic high-speed package machine for the biscuit, the chocolate, instant noodle, the drug and so on other goods, After the package, these goods are of beautiful appearance, strong sealing, health, and long storage.

Features

Parameter

Pillow Type Packaging Machine

Square, Rectangle, Circular, Ellipse, and Flake, etc.

| DXD-660 | DXD-420 | DXD-300 | |

|---|---|---|---|

| Max Capacity | 600 bags/min | 300 bags/min | 260 bags/min |

| Max Width of Film | 400mm 15.7in | 300mm 11.8in | 300mm 11.8in |

| Max Dia of Film | 350mm 13.8in | 350mm 13.8in | 350mm 13.8in |

| Bag Length | 55 – 200mm 2.2 – 7.9in | 60 – 400mm 2.4 – 15.7in | 90 – 450mm 3.5 – 17.7in |

| Bag Width | 25 – 100mm 1 – 3.9in | 35 – 100mm 1.4 – 4in | 40 – 140mm 1.6 – 5.5in |

| Bag Height | < 70mm < 2.8in | < 60mm < 2.4in | < 80mm < 3.1in |

| Dimension | 5600 * 1000 * 1700mm | 4300 * 850 * 1550mm | 4300 * 1000 * 1550mm |

| Total Power | 380V 50Hz 5.5kW | 220V 50Hz 3kW | 220V 50Hz 3kW |

Candy Packaging Machine

Candies, Lollipops, and Similar Products.

| DXD-1600 | DXD-1200 | |

|---|---|---|

| Max Capacity | 1600 pcs/min | 1200 pcs/min |

| Bag Length | 50 – 150mm 2 – 5.9in | 50 – 80mm 2 – 3.1in |

| Packing Length | 12 – 50mm 0.5 – 2in | 12 – 40mm 0.5 – 1.6in |

| Packing Width | 12 – 30mm 0.5 – 1.2in | 12 – 30mm 0.5 – 1.2in |

| Packing Height | 5 – 18mm 0.2 – 0.7in | 5 – 18mm 0.2 – 0.7in |

| Dimension | 3700 * 1650 * 1700mm | 2500 * 1350 * 1720MM |

| Total Power | 380V 50Hz 6kW | 220V 50Hz 4kW |

Capacity & Filling Volume depends on the product status and filling weight.

Our machines can be equipped with different cutters and chains to suit different sizes of packaging. Depending on your material and packaging requirements, we will complete the configuration for you before shipment.

Industries & Solution

IQF food with tray, Biscuits, Hamburger, Instant noodles, Articles for daily use, Drug sundries and So on.

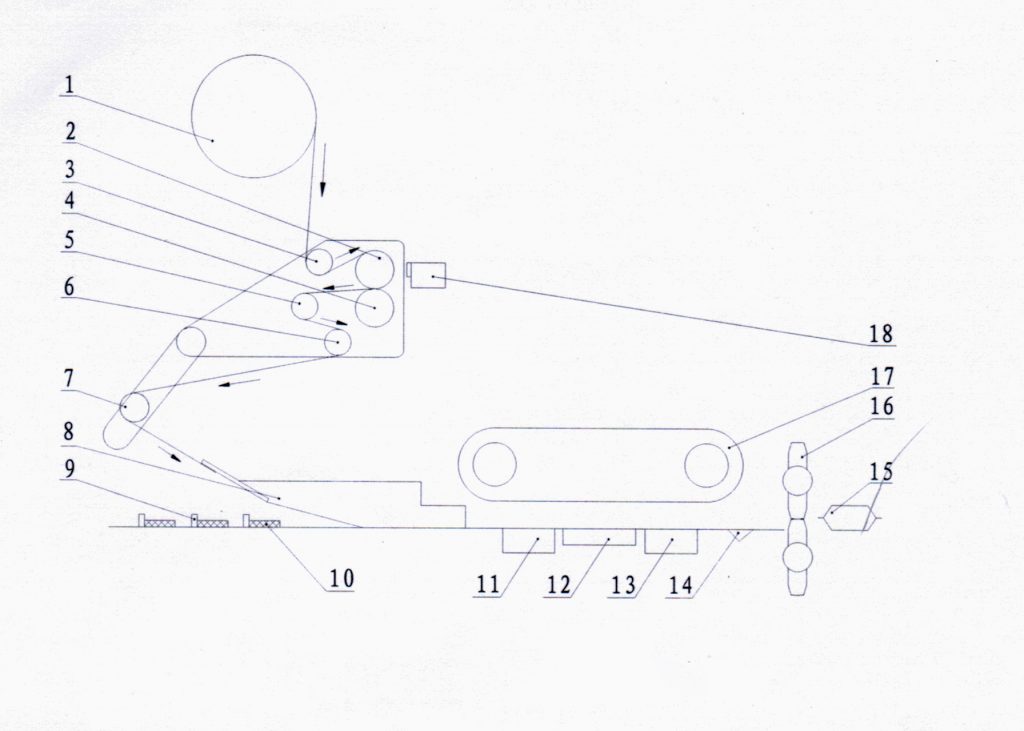

Working Principle

Complete Operational Principle

Put package 10 into the pushing chain track 9, entering into shaper 8. With the transmission of the feeding paper parts 1, 2, 3, 4, 5, 6, 7, the package paper is sent continuously and accurately into shaper 8. The package paper crosses the package material in the shaper through the act of shaper, making the package material in the shaper through the act of shaper, making the package paper pack on the article, and while the sending wheel 11 with brush 17 forward sends material, after being heated by heating copper 13 to make the vertical sealing complete. They continue going on forward through guide block 14, enter into the horizontal sealing cutter 16 to cut off the horizontal sealing, then finished go our product 15.

Shaper

Feeding Parts

The dynamic of transmission system is driven through several transmission units to rubber roller through the double chain wheel, and finally complete feeding paper.

Heat-Sealing Parts

Feeding wheel catches piping package material carried carried out by the shaper. And they are sent to vertical sealing roll wheel to finish its vertical hot mixing after being heated by heating copper and the hair brushes, vertical sealing hemming-stitch pressure flat. The horizontal sealing scissors turn to the vertical heat mixed package materials that have been heated from a cross sealing through horizontal sealing head and vertical sealing line. Then they are cut off at the same time through the relative motion of cutting tools and hammer anvil to send out from the terminal.