You get what you pay for, we provide very high-quality machines at a very low price. Below we will introduce the advantages of some of our Premade Pouch Packaging Machine and Automatic Vacuum Packaging Machine. If you have any doubts about our machines, please keep reading, there may be many very professional stuff, but we will try our best to make you understand.

Before we start, I want to let you know that we have been engaged in the packaging machinery industry for 20 years and currently sell more than 1,000 machines every year, which means that our scale is very large. Compared with other small manufacturers, it has an absolute advantage in after-sales——Our other customers have encountered almost all possible problems when using our machine, and we have solved them one by one. You will be very smooth when you use the machine.

In any case, even if you do not buy our machines, we also recommend that you choose the largest possible manufacturer, so as not to encounter unnecessary trouble after purchasing.

Patents

We have 21 inventions patents, 75 utility model patents, and 3 design patents. The following is a list of our patents, you can confirm these patents through the website of the CNIPA(China National Intellectual Property Administration), 浙江名瑞 is the name our company uses in China(This list may be outdated, everything is subject to CNIPA)

| Patent No/Authorized Number | Patent type | Application date/Authorization Date |

|---|---|---|

| 2021106206525 / CN113184283A | Inventions Patents | 2021.06.03 |

| 2021106206563 / CN113184280A | Inventions Patents | 2021.06.03 |

| 2021104545106 / CN112960182A | Inventions Patents | 2021.04.26 |

| 2020110017038 / CN112009762A | Inventions Patents | 2020.09.22 |

| 2020110017061 / CN112009763A | Inventions Patents | 2020.09.22 |

| 2019104875310 / CN110155746A | Inventions Patents | 2019.06.05 |

| 2017110217333 / CN107934086B | Inventions Patents | 2019.12.17 |

| 201610585501X / CN106043815B | Inventions Patents | 2018.8.14 |

| 2016105523955 / CN106043815B | Inventions Patents | 2018.2.23 |

| 201510450236X / CN105151731B | Inventions Patents | 2017.10.20 |

| 2014103052597 / CN104108486B | Inventions Patents | 2016.6.29 |

| 2014100583522 / CN103770973B | Inventions Patents | 2016.2.3 |

| 2010101294358 / CN101837845B | Inventions Patents | 2011.8.24 |

| 2018103490142 / CN108557174A | Inventions Patents | 2018.04.18 |

| 2018103487008 / CN108408141A | Inventions Patents | 2018.04.18 |

| 201711268522X / CN107934039A | Inventions Patents | 2017.12.05 |

| 2016105741714 / CN106043812A | Inventions Patents | 2016.07.21 |

| 2016105856690 / CN106043796A | Inventions Patents | 2016.07.21 |

| 201410368277X / CN104150052A | Inventions Patents | 2014.07.30 |

| 2014101617668 / CN104003024A | Inventions Patents | 2014.04.21 |

| 2012104415546 / CN102920360A | Inventions Patents | 2012.11.08 |

| 2012103049627 / CN102777560A | Inventions Patents | 2012.08.26 |

Many people may not know that it is very easy to apply for design patents in China, followed by utility model patents. The most difficult one is invention patents. Invention patents require substantial innovation and will be subject to strict review(Only about 1/4 of our inventions patents application was approved). Many machinery companies may claim to have a lot of patents, but they may only have design patents that have no technical content in the industry.

Hardware

Transmission Part

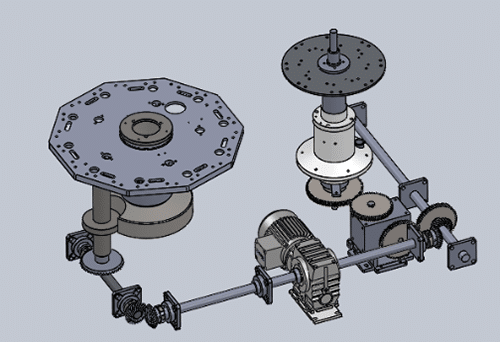

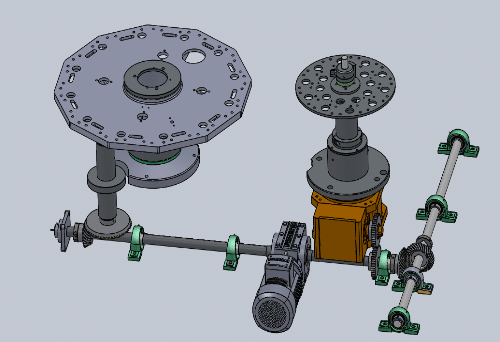

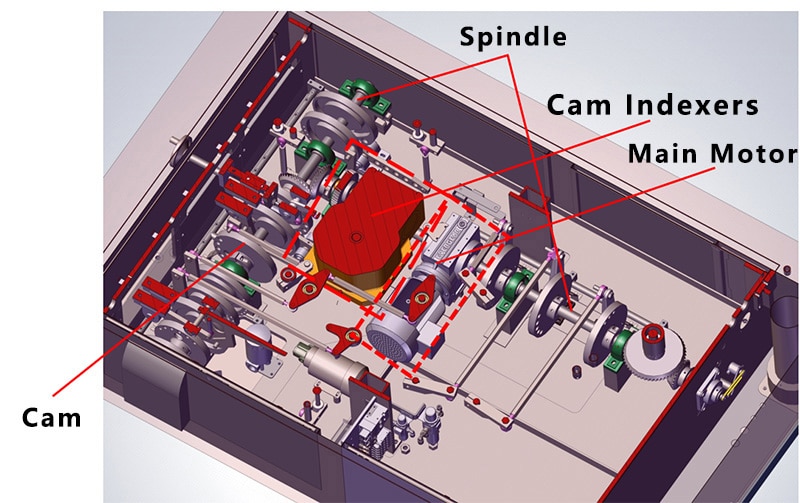

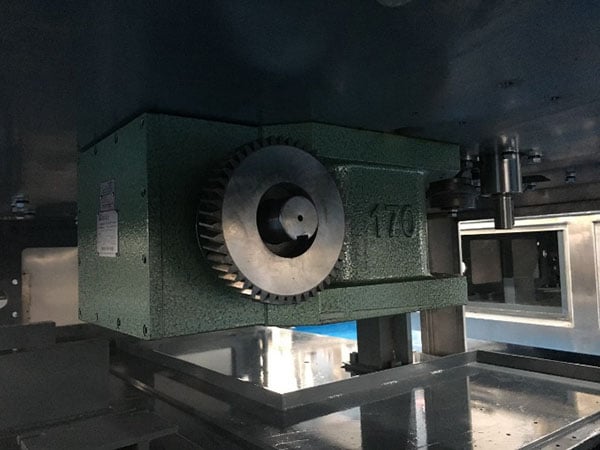

Our transmission has a T-shape layout, which is more concise than the concave-shape layout used by some machines. This kind of transmission is more efficient and more stable.

In order to ensure the stable operation of the machine at high speed, our cam indexers are specially customized. They have particularly large torque, sealed lubrication, and very high accuracy. The entire transmission part has undergone a destructive test of 180 times per minute for 3 months.

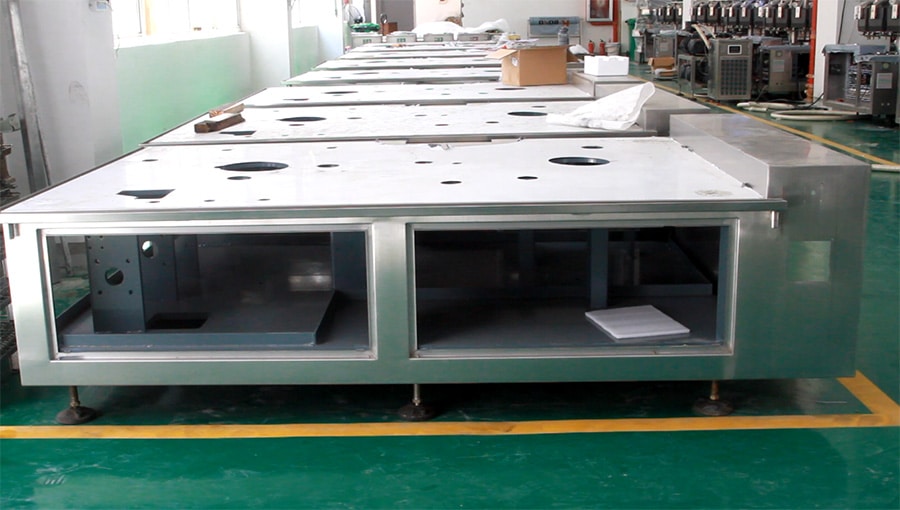

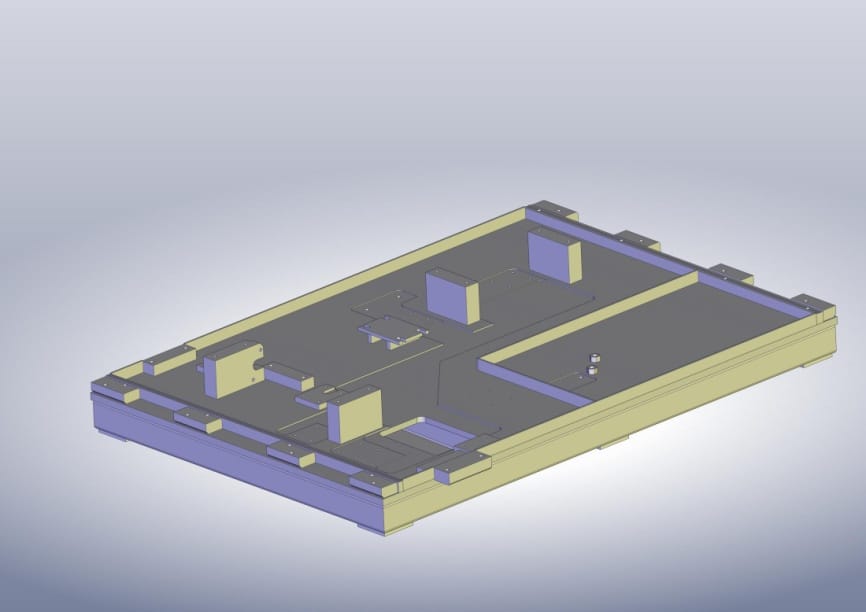

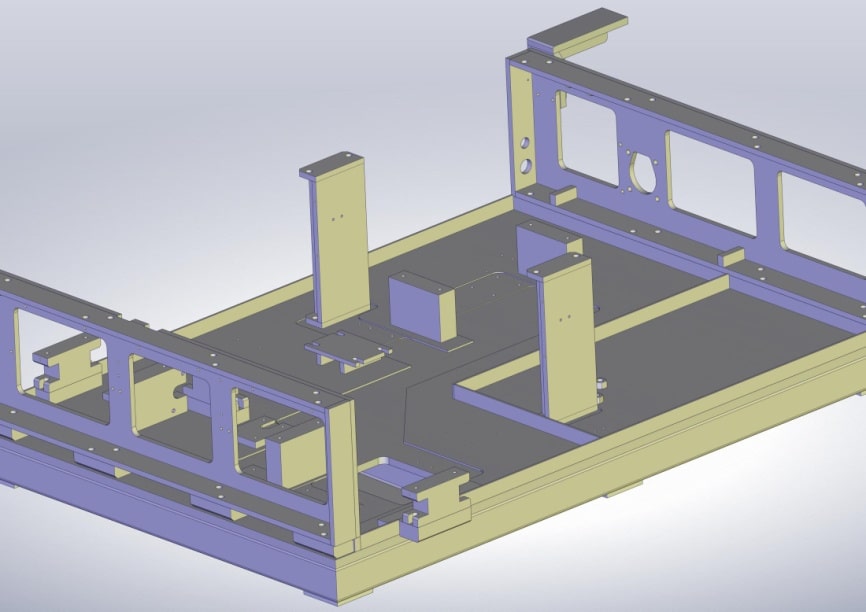

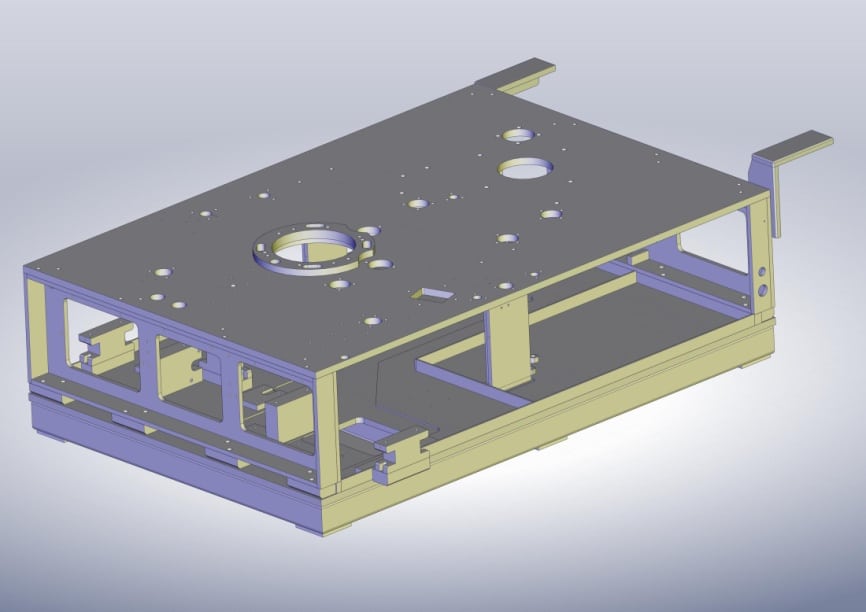

Frame

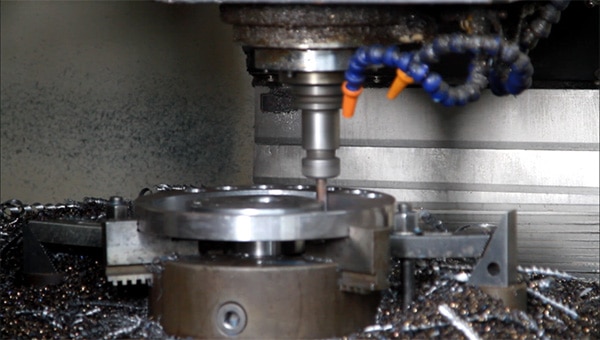

Processes: raw materials(special carbon steel) → rough finish → soldering → temper → CNC finish machining → assembly

The frame adopts the integrated processing method of welding and milling to ensure that the frame is not easily deformed. It directly determines the stability and precision of the equipment. The frame plate is twice the thickness of the ordinary frame, and the chassis thickness is 30mm, making the weight of the machine up to 3.5 tons(The heavier the frame, the more stable the machine). These all directly determine the stability and precision of the equipment.

lubrication

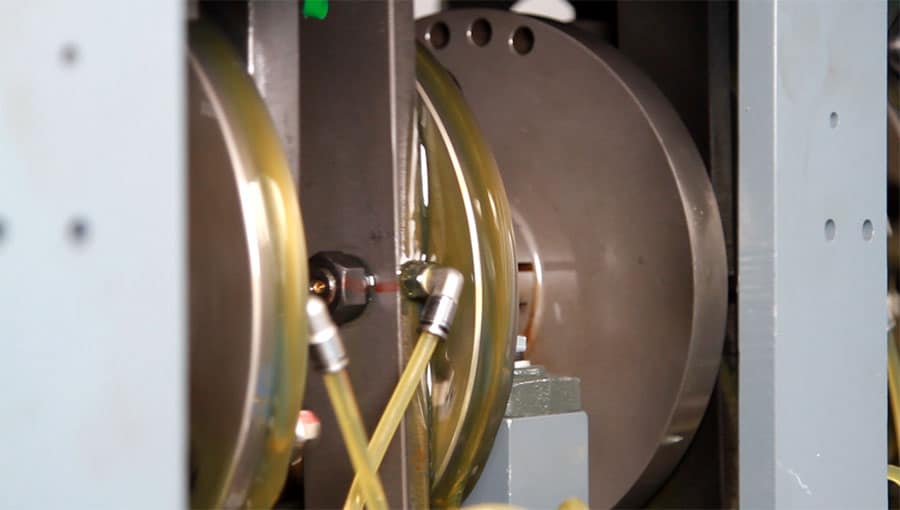

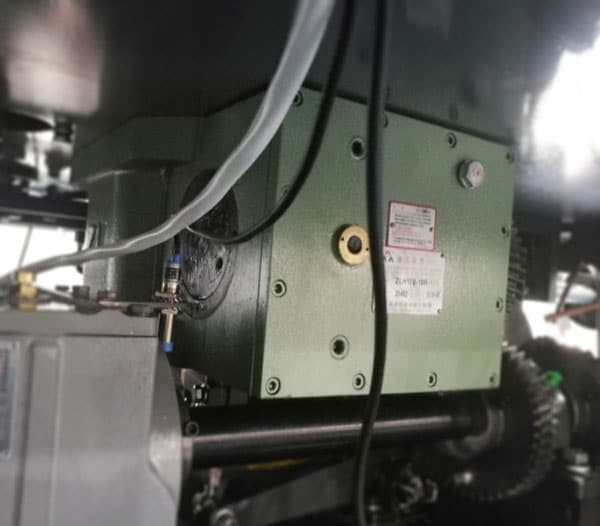

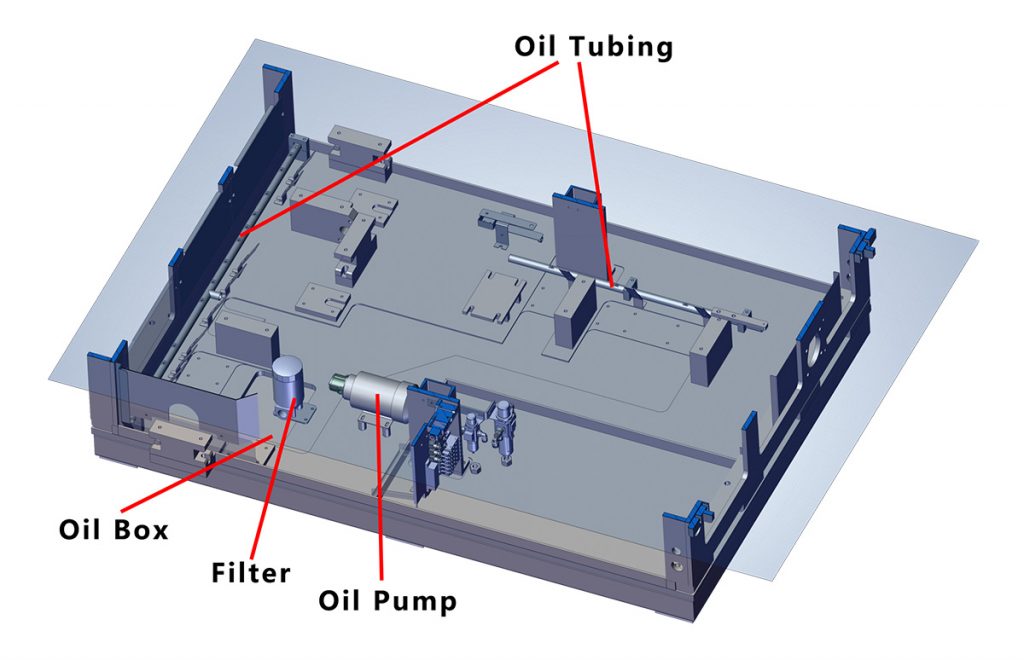

Our machine adopts a circulating oil supply system, which directly injects into the inside of each bearing and the surface of gears and cams to form an oil film to eliminate the heat of high-speed operation and ensure that the cam is not broken for life.

Cam

Using curved indexing cam: The structure is medium-loaded, high-speed, and high-precision indexing. The box body is closed, the whole is soaked in oil, it is not easy to wear and no impurities enter. As mentioned before, our cam will not be damaged, so we can provide a lifetime warranty.

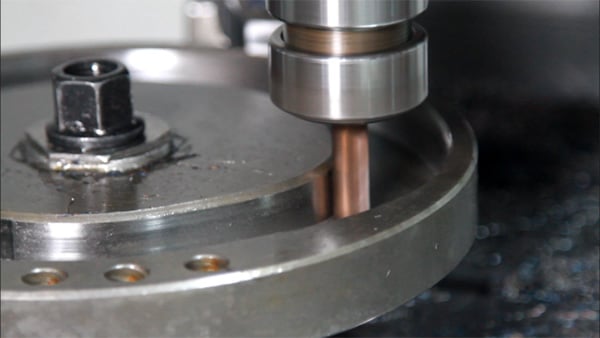

Cam processing technology: Blank → Fine Turning → Rough Milling → Drilling and Tapping → Quenching → Sandblasting (surface treatment) → Internal Grinding → Fine Milling → Coding → Wire Cutting → Blackening

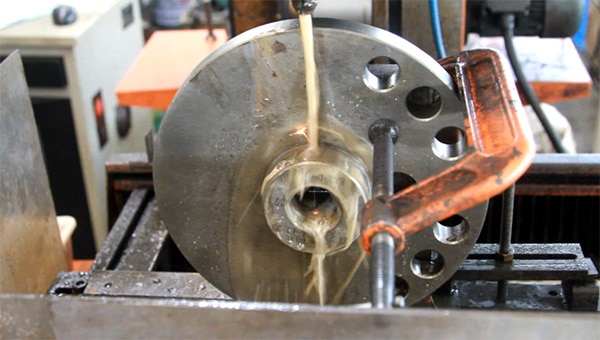

Vacuum Chamber

The Vacuum Chamber is made of aviation aluminum directly engraved and milled in the computer processing center to ensure airtightness and durability.

The specific process is: original blank → milling → oxidation

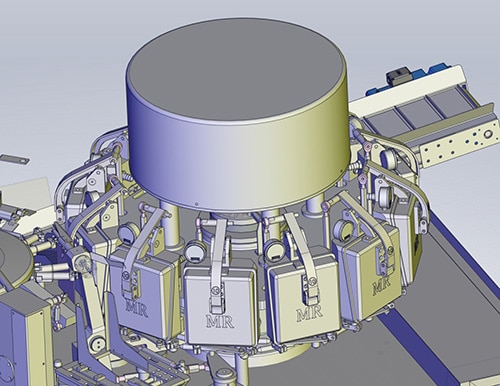

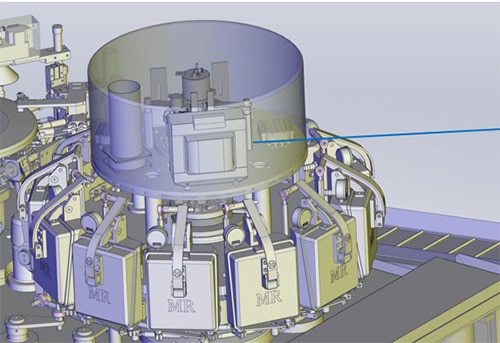

Given Bag Turntable

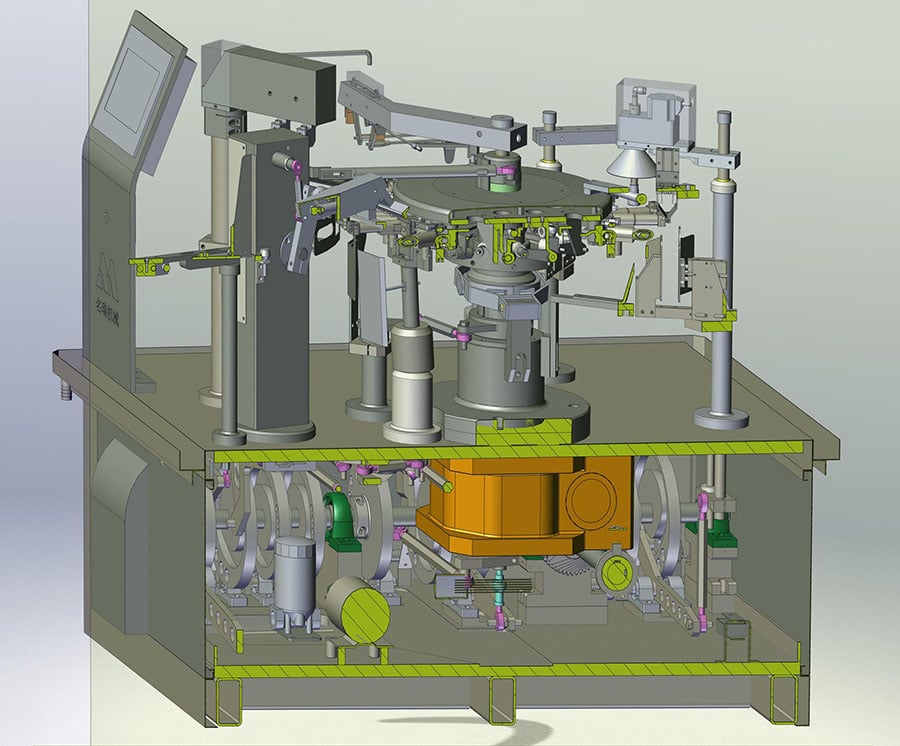

The original high-speed bag-feeding turntable adopts a 10-station design. More stations provide more industrial packaging process requirements under high-speed conditions. The strengthened turntable seat and turntable shaft sleeve are made of 304 stainless steel, which has great anti-corrosion performance improve.

The center shaft is integrally processed with imported special steel (post-processing with 45 steel welded flanges for ordinary machines).

Whether it is bag loading, bag opening, or bag support, it is designed and manufactured at a rate of 120 times per minute. The bag support does not need any slot and roller, and the driving only relies on the cam, which is still stable and does not shake at a speed of 100 times per minute.

Vacuum Turntable

The vacuum turntable bearing seat, bearing and turntable are all redesigned and manufactured, and the rigidity and strength are more than twice that of the others machine.

The outlet direction of vacuum pipes, air pipes, water pipes, etc. can be adjusted according to the layout of the customer’s workshop.

Cleaning and Maintenance

Above the frame table, the part that may be in direct contact with the package is made of 316L stainless steel, and the other parts without special process requirements are made of 304 stainless steel, and the surface is brushed or polished. When cleaning, just wipe it with a towel and detergent.

Above the frame table, the transmission bearing adopts stainless steel bearing or igus oil-free bearing. The rolling bearing is equipped with a waterproof oil seal and is equipped with an oil injection hole, which can not only fully maintain the lubrication performance and life of the bearing, but also prevent the corrosion of the bearing.

Above the frame table, all installation holes are treated with waterproof glue to prevent water from entering the frame.

Software

MServer

MServer system, through the Internet (Ethernet, 4G, Wi-Fi, etc.) to transmit data or programs of a large number of industrial equipment in different areas to the remote cloud data center to realize remote data monitoring, equipment diagnosis, program maintenance, fault alarm, and other functions. Provide users with a simple and reliable industrial Internet data remote transmission program.

| Component | Description |

|---|---|

| Device Side | FBox and the connected device controller, HMI and instrument, etc. |

| Server | MServer cloud server group or users build private cloud server,can connect to MES system. |

| Client | PC client/WEB client, mobile APP, and OPC docking with the host computer, API (HTTP or SDK). |

Protective Function

Software Copyright

We have four software copyrights, which correspond to our different machine models, you can confirm these software copyright through the website of the CNIPA(China National Intellectual Property Administration).

| Name | No. | Date |

|---|---|---|

| MR8-200RN V1.0 | 2018SR889576 | 2018.9.6 |

| MRZK-160N V1.0 | 2018SR894779 | 2018.9.13 |

| MRZK-120N V1.0 | 2018SR890884 | 2018.9.14 |

| MRZK-90N V1.0 | 2018SR890873 | 2017.8.26 |