IP is the abbreviation of ingress protection. It is an international marking system used by manufacturers to indicate that the product shell and the inside of the shell are protected. The source is the standard IEC60529 of the International Electrotechnical Commission. Different regions may have different protection standards: British Standard BS EN 60529:1992, European Standard 60509:1989 and internationally, they meet EN 60529 certification.

Common and familiar smart devices or machinery have a protection standard, and the protection standards are different for liquids and solids.

The common standard of protection is usually in the form of IP plus two numbers, such as: IP45. The meanings of these two numbers are different. Generally speaking, the first number refers to the solid protection level, the second digit indicates the level of protection that the enclosure provides against harmful of water.

Businesses usually describe how their products are dustproof or waterproof. But how to let consumers know, you need the help of IP rating.

IP rating is very important for manufacturers. To obtain the IP rating of the product, a formal and professional company certification is required. After the test, the certification company will provide a digital IP rating for the product based on the test result. This can provide consumers with a reference basis for product selection.

The first number after IP represents different solid protection requirements. The solid protection is mainly to prevent the intrusion of external particles.

The number 0 is no protection against solids. Expose the solid product directly to the air without any protective treatment.

1 is to block particles larger than 50 mm in diameter. Under this protection, it can effectively prevent large-area contact of the human body, but for small areas of tissue, such as palms and backs of hands, it cannot provide protection.

2 is to protect objects with a diameter greater than 12.5 mm. This can effectively organize any part of the human body.

3 means to block dust particles above 2.5 mm in diameter. This number indicates that an object the size of a screwdriver can be prevented from entering.

The protection of the number 4 can block up to 1 mm of dust particles. Most wires, slender screws, and even some larger ants can be blocked from the outside.

5 and 6 indicate that protection can achieve the effect of dust prevention. The protection effect of 6 is better, which can completely cut off dust. Meanwhile, the protection effect of 6 will apply vacuum to achieve complete protection. The 5’s protection may not be as complete a barrier as the 6’s. But the solid protection represented by the number 5 can also keep out most of the dust in the air. Perhaps the rest of the dust may enter the shield through the gap that people can not notice, but such errors and omissions will not have any effect on the product itself.

Water and excessive humidity are deadly enemies of the normal operation of electronic equipment and machinery. Rainy weather and normal running water cleaning will affect the internal components of the device, and short-circuit failures may occur.

The second number after IP represents different liquid protection requirements. Liquid protection is to block the entry of liquid to prevent the phenomenon of deterioration due to moisture.

0 indicates that no precautions have been taken.

1 is to prevent dripping. The precautionary standard is that when the product is installed vertically on the turntable and rotated at 1RPM, the water droplets that drip vertically will not affect the product.

2 indicates that the drops fall at an Angle of 15 degrees with the product, but it will not affect the use of the product.

3: Spray protection. Set the sprayed water column and the machine at an angle of 60 degrees, and observe the use of the product at this time.

4 is splashing. This number requires the liquid to be splashed on the product at any angle without affecting its use.

5 is able to withstand low pressure water column test. When the liquid is sprayed on the equipment shell from any angle through the water column from the 6.3 mm nozzle, it will not produce negative effects.

6 is able to withstand high-pressure water column tests. The pressurized water jet ejected from the 12.5 mm powerful nozzle can be sprayed onto the equipment from any angle without affecting the use of the equipment.

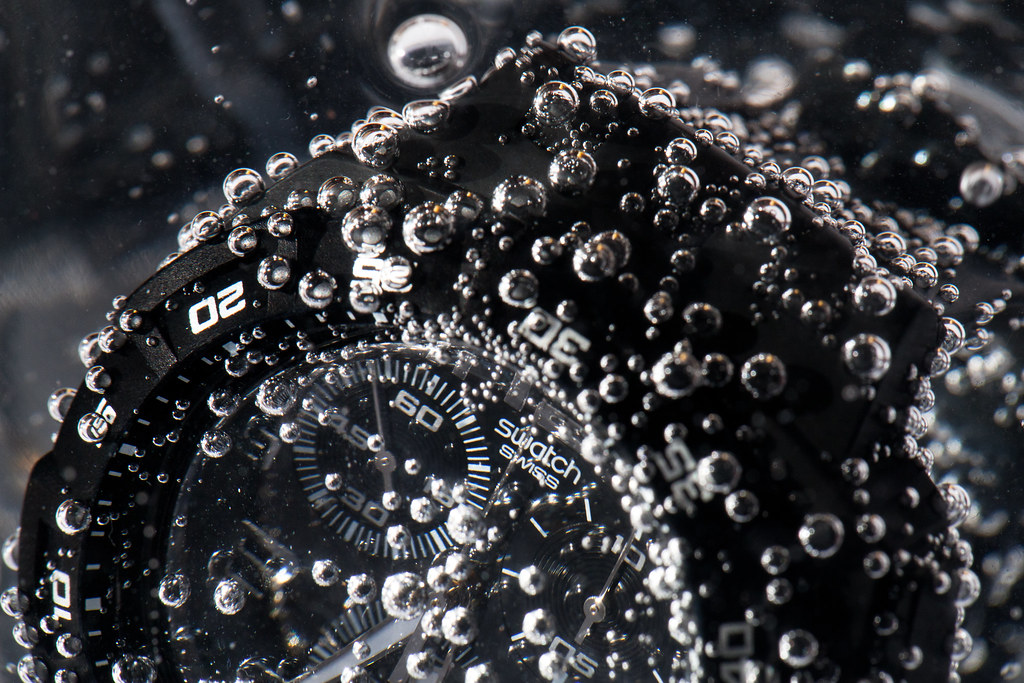

The number 7 indicates immersion to a depth of about 1 m. When the enclosure is immersed in a liquid with a depth of 1 m under the specified pressure and time conditions, this number represents protection from harmful amounts of liquid entering the equipment.

8 indicates immersion of 1m or more. The number 8 means the device should be able to immerse for at least 1 hour.

9K is a high temperature and high pressure water column test. The equipment can withstand close-range high temperature and high pressure water column impact under the conditions specified by the manufacturer within 2 minutes of the test time.

There are also additional attainable ratings for specific protection:

D – Wire

F – Oil resistant

H – High voltage

M – Moving during water test

S – Standing still during water test

W – Weather resistant

Most electronic products such as smart phones and earphones have a protection level.

Take the smart devices we are familiar with, most smart devices can achieve IP68 protection level. This means that the electronic products under this protection level can be absolutely dustproof and excellent waterproof, and can be immersed in liquid for at least 1 hour.

The protection level of electrical sockets is generally IP54. Protection at this level can effectively prevent accidental entry of wires with a diameter greater than 1 mm.

In the medical field, improving the IP protection level is also an important matter. The cleaning of medical equipment requires that the equipment can withstand the sterilization process without affecting the next use of the equipment. Such protection requirements require the equipment to meet the protection requirements of IP54, IP65 or higher.

However, it is worth noting that any equipment that is said to have a waterproof effect is actually not 100% resistant to water penetration. Waterproof refers to the protection of the surface of the article so that it is not easily penetrated by water. Therefore, even if the level of liquid protection is higher, attention should be paid to reducing contact with liquids.

The content and opinions of this article come from external authors and do not represent the company. In case of errors or copyright questions, please send to echomachinery@echomachinery.com