MRZK Series

Fully Automatic Rotary Vacuum Sealing Machine

| Capacity | Up To 150 BPM |

| Bag Width | 55 – 300mm 2 – 11.8in |

| Filling Volume | 5 – 1000g |

| Bag Length | ≤ 450mm ≤ 17.8in |

Vacuum packaging machines are used to evacuate the air around perishable goods such as food products like pickles, dried bean curd, chicken feet, fried fish, and so on whose extension of shelf life is desired. The machine can realize measuring, filling, vacuum, sealing, product output automatically.

Features

Parameter

| MRZK 100 Series | MRZK12S-100 | MRZK14-100F | MRZK14-130E | MRZK12-160B |

|---|---|---|---|---|

| Bag width | 50 – 100mm 2 – 3.9in | 55 – 100mm 2.2 – 3.9in | 60 – 130mm 2.4 – 5.1in | 80 – 160mm 3.1 – 6.3in |

| Bag length | ≤ 180mm ≤ 7.1in | ≤ 220mm ≤ 8.7in | 60 – 220mm 2.4 – 8.7in | ≤ 320mm ≤ 12.6in |

| Filling Volume | 5 – 50g | 5 – 50g | 5 – 50g | 10 – 100g |

| Capacity | ≤ 150bags/min | ≤ 100bags/min | ≤ 85bags/min | ≤ 80bags/min |

| Package Accuracy | Error≤ 1% | Error≤ 1% | Error≤ 1% | Error≤ 1% |

| MRZK 200/300 Series | MRZK10-200A | MRZK10-240A | MRZK10-260 | MRZK10-280 | MRZK10-300 |

|---|---|---|---|---|---|

| Bag width | 90 – 200mm 3.5 – 7.9in | 130 – 240mm 5.1 – 9.4in | 140 – 260mm 5.1 – 10.2in | 170 – 280mm 6.7 – 11in | 190 – 300mm 7.5 – 11.8in |

| Bag length | ≤ 320mm 12.6in | ≤ 320mm 12.6in | ≤ 360mm 14.1in | ≤ 450mm ≤ 17.8in | ≤ 450mm ≤ 17.8in |

| Filling Volume | 10 – 1000g | 10 – 1000g | 10 – 1000g | 10 – 1000g | 20 – 1000g |

| Capacity | ≤ 50bags/min | ≤ 50bags/min | ≤ 40bags/min | ≤ 35bags/min | ≤ 35bags/min |

| Package Accuracy | Error≤ 1% | Error≤ 1% | Error≤ 1% | Error≤ 1% | Error≤ 1% |

| MRZK Nitrogen Series | MRZK12-161 | MRZK12-163A | MRZK10-241 |

|---|---|---|---|

| Bag width | 80 – 130mm 3 – 5.1in | 55 – 100mm 2 – 3.9in | 90 – 160mm 3.5 – 6.3in |

| Bag length | ≤ 190mm ≤ 7.5in | ≤ 270mm ≤ 10.6in | ≤ 240mm ≤ 9.4in |

| Thickness | ≤ 50mm ≤ 2in | ≤ 50mm ≤ 2in | ≤ 50mm ≤ 2in |

| Capacity | ≤ 50bags/min | ≤ 60bags/min | ≤ 50bags/min |

| Package Accuracy | Error≤ 1% | Error≤ 1% | Error≤ 1% |

Capacity & Filling Volume depends on the product status and filling weight

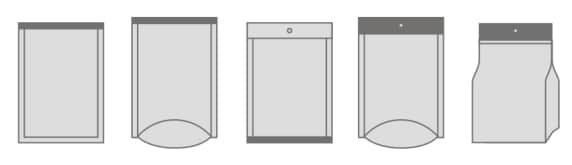

Bag Style

Industries & Solution

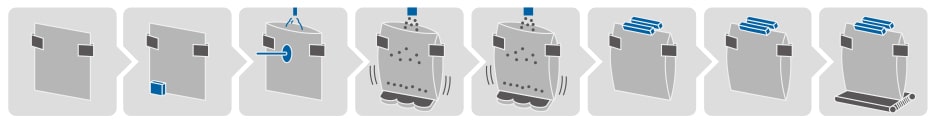

Packaging Process

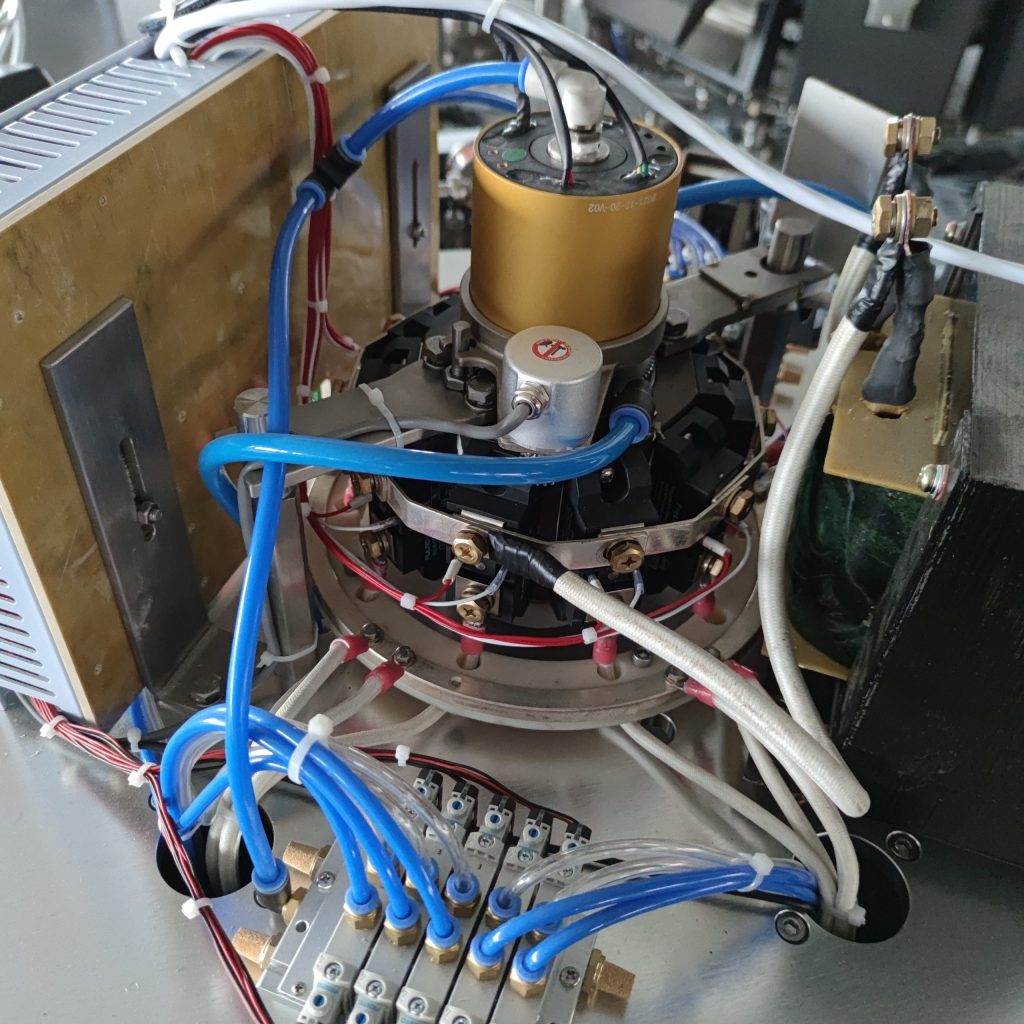

Bag Feeding Turntable

- Giving Bag —— Feed many pouches or bags in the bag magazine, our main bag magazine can move up and down, you can feed bags very easily when it moved down, and when it moved up, there are a mechanical arm with two vacuum caps will take the bag up and then transmit it to the mechanical gripper on the rotary table.

- Date Printing —— According to the actual production and packaging needs, different types of coding machines are configured to print the date and batch number on the packaging bag.

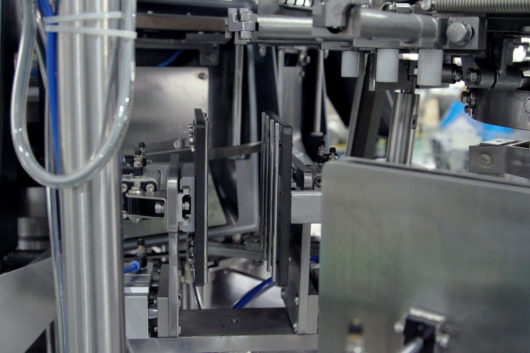

- Opening Bag —— While the suction cup opens the opening of the packaging bag, air is sprayed from the upper nozzle to blow open the bottom of the packaging bag, the packaging bag support plate is inserted into the opening of the packaging bag, and the packaging bag enters the next station.

After inserting the bag support plate into the bag opening, the detection of whether there is a packaging bag and whether the opening of the bag is opened is completed. If there is no packaging bag or there is no opening to open the packaging bag, the next station will not feed. - Filling & Consolidate 1 —— According to different packaging materials, different feeders are configured at this station to complete the automatic or semi-automatic delivery of materials.

- Reserve

- Reserve

- Reserve

- Bag straightening —— Straighten the bag and check whether there are materials in the bag at the same time. If there is no material in the packaging bag, it will not be transferred into the vacuum chamber.

- Transfer —— The transfer manipulator between the two turntables transfers the packaging bags from the bag feeding turntable to the vacuum turntable. The packaging bag with the mouth of the packaging bag not opened or without materials added will not be passed into the vacuum chamber, and the packaging bag can be recycled and used again after it is dropped at this station.

- Reserve

Vacuum Turntable

- Transfer —— The packaging bag is transferred from the bag feeding turntable to the vacuum turntable, and the packaging bag enters the vacuum chamber.

- Vacuum Chamber Cover —— The vacuum chamber is closed, and the vacuum in the vacuum chamber that has been sealed is recovered.

- Semi-vacuum —— Evacuate most of the air into a semi-vacuum state.

- First Vacuum —— Evacuate all the air, there are only a few bubbles in the bag.

- Second Vacuum —— Pump the air bubble into a full vacuum state.

- Third Vacuum —— Further into the vacuum state.

- Sealing —— The sealing cylinder extends, and the sealing electric heating plate is energized to generate heat, Sealing bag.

- Cooling Exhaust —— The sealing electric heating piece is cut off, and the cooling water cools the bag mouth to normal temperature.

The vacuum chamber is connected to the atmosphere, and the atmosphere enters the vacuum chamber. - Uncover and Move Out —— The vacuum chamber is opened, and the packaged product falls onto the finished product conveyor belt.

Safety

Learn More

If you still have doubts about Echo Machinery, read our —— Why Choose Packaging Machine of ECHO Machinery

We have compiled a list to answer some common questions from customers —— FAQ

Our newly developed machine for automatic flatten materials —— Vacuum Flatten Packaging Machine

Regarding the maintenance of the machine, you can read —— Packaging Machine Maintenance Guide