The R&D team of ECHO Machinery Co., Ltd. pioneered the Vacuum Flatten Packaging Machine MRZK-200P in China.

Advantage

While reducing production costs, MRZK-200P also improves the hygiene standards of the entire line and the efficiency of the packaging line, completely freeing hands and maximizing profits.

MRZK-200P is the first packaging machine with a horizontal vacuum chamber in China. The most traditional material shaping method is to use manual flattening. Too much manual involvement in the production line will cause health and safety hazards. Say goodbye to traditional vacuum chambers and traditional shaping methods, MRZK-200P vacuum processes, and seals materials in the vacuum chamber in a horizontal state. Reduce the participation of personnel on the production line, reduce production costs, improve production efficiency, and maximize profit conversion.

Innovation

The R&D team of ECHO Machinery Co., Ltd. created an original horizontal vacuum chamber, which completely throws away the traditional primitive inefficient method. The machine vibrates and shapes the material in the package in a horizontal state to ensure the overall uniform distribution of materials.

The machine beating replaced the previous manual operation, improved efficiency, and reduced material hygiene and safety risks. We insist on innovation on the road of packaging, considering the needs of customers and consumers. We abandoned the traditional way of pressing the material by hand, the fully automated process runs through the entire production line to reduce the contact between people and materials on the production line. We do not destroy the original form of the material while discharging the air in the packaging.

Before MRZK-200P, 100 degrees vacuum has always been an unachievable standard on the market, but MRZK-200P turns this impossible into a possibility.

A vacuum of 100 degrees is a complete vacuum. Such a vacuum environment is more conducive to the preservation of the items in the package. As far as food is concerned, extending the shelf life of food brings many benefits to both consumers and manufacturers.

The successful development of the horizontal vacuum chamber is an important change in packaging machinery, and vacuum brings a new possibility to packaging.

Sealing process

A good vacuum packaging should be as close as possible to perfection in every detail. Not only the main part where the material is located, but also the sealing treatment should be strictly controlled. Clean seal is the basic, and clean seal is the guarantee of good vacuum packaging effect. After multiple reshaping, the material packaging effect reaches a high standard. Sealing in the vacuum chamber ensures sanitation and safety, and also ensures the vacuum tightness of the packaging. MRZK-200P has carried out more stringent treatment on the packaging seal to ensure that the seal is clean and free of impurity. The sealing of the package treated by the previous semi-automatic vacuum equipment in the past always carried more or less sundries and defects. The seal folding, containing oil and material, etc. are not uncommon. Such vacuum packaging is easy to leak air, increasing the risk of loss. 200P can be smoothed and shaped in one machine, and the finished packaging products are in high quality, which brings new surprises and better experience to consumers.

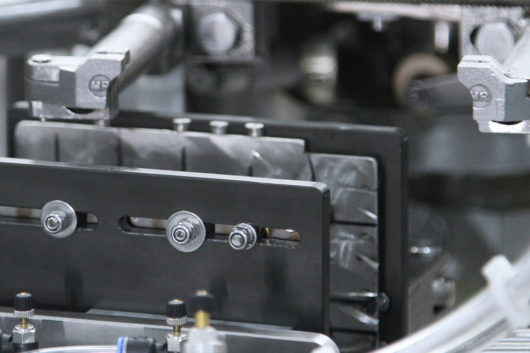

High-quality accessories

Every time we make unremitting attempts, we hope that we can get satisfactory results. ECHO Machinery’s R&D team leads the industry by discarding additional vacuum accessories and achieve 100 degrees vacuum. MRZK-200P is at the forefront of the industry, creating complete vacuum conditions to extend the storage time limit of materials, making materials safer and consumers more assured. The divider plate of imported material, -0.9 to -0.8 MPa negative pressure suction is more thorough. In addition, the design of MRZK-200P is focused on each user. According to the user’s operating requirements, MRZK-200P is designed with a simple operation interface and one-key operation, even a novice who uses it for the first time can easily get started.

In 2020, the market size of vacuum packaging machines has reached $12.9 billion. In 2025, the market size is expected to reach $16.4 billion, with a compound annual growth rate of 5%. People’s requirements for food storage are increasing, which helps the development of the entire vacuum packaging machinery industry. This is indeed the case.

There are many foods in the market that use vacuum packaging, but due to technical or mechanical problems, the vacuum packaging effect is not particularly ideal. It is not uncommon for materials and grease to be mixed in the seal of the packaging bag, or the packaging seal is folded. With the continuous expansion of the vacuum packaging market, people’s requirements for vacuum packaging have been in an increasingly stringent development and change.

To facilitate transportation and sales of products, flexible packaging is always more selected by food manufacturers in food packaging. Flexible packaging also promoted the innovation of packaging machinery.

The Asia-Pacific region is the main market for vacuum packaging, followed by Europe. In the Asia-Pacific region, with the increase in per capita disposable income, people’s expenditure on food packaging has also begun to increase. More and more health and safety incidents are also updating and improving people’s hygienic standards for food packaging. People always hope that vacuum-packaged food can have better packaging effects and higher packaging quality.

For packaging machinery manufacturers, how to improve packaging quality has also become an important direction of machinery research. A good vacuum packaging machine must not only have a high-quality packaging appearance, but also a good vacuum effect. In addition, how to truly realize 100-degree vacuum packaging is also an important problem to be solved in the field of mechanical packaging.

The reform of food packaging machinery has attracted much attention. The increase in disposable income and the improvement of living standards have caused people to pay more attention to food hygiene and safety, packaging details, etc. The development and production of MRZK-200P is precisely because of the changes and new requirements that people have produced in these aspects.