History

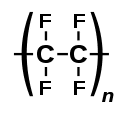

For a long time, the problem of sticking sticky objects to metal remained unsolved, and in 1938, Roy J. Plunkett of the DuPont Company stumbled upon a material, Teflon(PTFE):

(Teflon) was an accidental invention—unlike most of the other polymer products…. Plunkett’s first assignment at DuPont was researching new chlorofluorocarbon refrigerants…. When he and his helper prepared a cylinder for use, none of the gas came out——yet the cylinder weighed the same as before. They opened it and found a white powder, which Plunkett had the presence of mind to characterize for properties other than refrigeration potential. He found the substance to be heat resistant and chemically inert, and to have very low surface friction so that most other substances would not adhere to it.He found the substance to be heat resistant and chemically inert, and to have very low surface friction so that most other substances would not adhere to it. Plunkett realized that against the predictions of polymer science of the day, TFE had polymerized to produce this substance—later named Teflon—with such potentially useful characteristics.

Teflon is actually called Polytetrafluoroethylene (PTFE), and Teflon is the trademarked name.

It was patented by DuPont Company in 1941, trademarked as “Teflon” in 1944, and subsequently developed under such names as Teflon AF, Teflon FEP, Teflon FFR, Teflon NXT, and Teflon NXT, Teflon PFA and some other listed products like that. It was in 1954 when French engineer Marc Gregoire and his wife Colette invented the Nonstick pan, and the material began to find its way into the homes of ordinary people. The most famous use of PTFE was at the 2008 Beijing Olympic Games, as the Olympic Games aquatic events arena Water Cube, the exterior of which was completely covered with PTFE, which is the largest concentration of PTFE in the world.

PTFE is resistant to acids, alkalis, high temperatures and is virtually insoluble in all known solvents, and most importantly he has a coefficient of friction of only about 0.1, making it an ideal oil-free lubricating material, which is the only known surface to which the gecko cannot currently attach.

| MF | (C2F4)n |

| CAS Number | 9002-84-0 |

| UNII | E1NC1JVS3O |

| EINECS | 618-337-2 |

| Melting Point | 327°C |

| Boiling Point | 400°C |

| Density | 2.15 g/mL (25°C) |

| Merck | 14,7562 |

| Stability | Stable unreactive with most materials. Incompatible with molten alkali metals, fluorine and other halogens, strong oxidizing agents. |

| NIST Chemistry Reference | Polytetrafluoroethylene, annealed(9002-84-0) |

| IARC | 3 (Vol.19, Sup 7) 1987 |

| EPA Substance Registry System | Polytetrafluoroethylene (9002-84-0) |

Application on Multihead Weigher

As a matter of course, PTFE is also used in multihead weigher as a non-stick material. A typical example is cheese packaging machine, Cheese has a very high viscosity. Ordinary metals will stick to its surface, blocking the weight cup and making the weighing inaccurate. However, a machine with a PTFE coating on the surface can solve this problem perfectly:

As the video shows, cheese was weighed smoothly, just like any other material. In addition to cheese, it also works well on high viscosity gummy candy, brown sugar, and candied fruit. You can check out our Cheese Packaging Machine to know more.

And regarding its food safety, some people do worry that PTFE is toxic, so many cooks refuse to use Nonstick pan with PTFE. However, this is not a problem, DuPont conducted a large number of experiments, it is completely non-toxic at room temperature, when the temperature reaches 260 ° C began to deteriorate, at 350 ° C began to decompose, although it will produce smoke at 200 degrees Celsius, but according to research, this kind of gas toxicity is very low, It is not even as toxic as the smoke produced by general edible oil, and in the packaging process, it is impossible to reach such a temperature, so there is no need to worry about the food safety of PTFE coated multihead weigher.

Compared with ordinary multi-head weigher, PTFE-coated multi-head weigher increase the cost of PTFE coating, making the equipment more expensive. Different PTFE prices and performance are slightly different, and different multi-head weigher have different surface areas. In general, PTFE coating will Make the weigher about 10-20% more expensive. it’s totally worth it for sticky products.

Refer:

http://www.rjchase.com/ptfe_handbook.pdf

https://web.archive.org/web/20071014063923/http://socrates.berkeley.edu/~peattiea/research_main.html

https://web.archive.org/web/20100620052747/http://www.chemheritage.org/classroom/chemach/plastics/plunkett.html

https://www.commonchemistry.org/ChemicalDetail.aspx?ref=9002-84-0

https://webbook.nist.gov/cgi/cbook.cgi?ID=9002-84-0&Units=SI

https://patents.google.com/patent/US2230654A/en

Zapp JA, Limperos G, Brinker KC (26 April 1955). “Toxicity of pyrolysis products of ‘Teflon’ tetrafluoroethylene resin”. Proceedings of the American Industrial Hygiene Association Annual Meeting.