We are all familiar with packaging. The items we come into contact with in our daily life and the products displayed in shopping malls are also inseparable from packaging. Clothing and luggage items may be manually packaged after purchase, but the packaging is not entirely dependent on labor. More products are packaged before they leave the factory. The coverage of the packaging machine industry has gradually expanded, and packaging machinery has gradually become popular, so the vast majority of packaging of that type of product is dependent on machinery.

The application of packaging machinery involves food, medicine, daily chemical, hardware, lighting, furniture and other industries. Powder, granules, liquids, etc. can be packaged in the packaging machine. The designer of the packaging machine will adjust the packaging machine according to market demand. By adding different auxiliary machines, the efficiency of packaging machinery is maximized. Through different auxiliary machines, different packaging purposes can be realized.

The competition of packaging machinery is becoming increasingly fierce, and the trend of packaging machinery with industrial automation is becoming more and more obvious. With the improvement of the level of packaging machinery, and the development of packaging equipment is developing in the direction of multi-function, high efficiency and low consumption.

Convenience

The intelligent development of packaging machinery has brought people a lot of convenience. Most packaging machinery can be controlled by smart devices. After the addition of smart devices, the use of machinery has become convenient and intelligent. Generally, the machinery manufacturer will debug the machinery before leaving the factory. After the user receives the machine, he only needs to perform simple routine operations to use the machine normally. The packaging equipment is connected to the mobile smart device through the network, so that the real-time status of the packaging machinery can be viewed on the mobile terminal.

Efficient

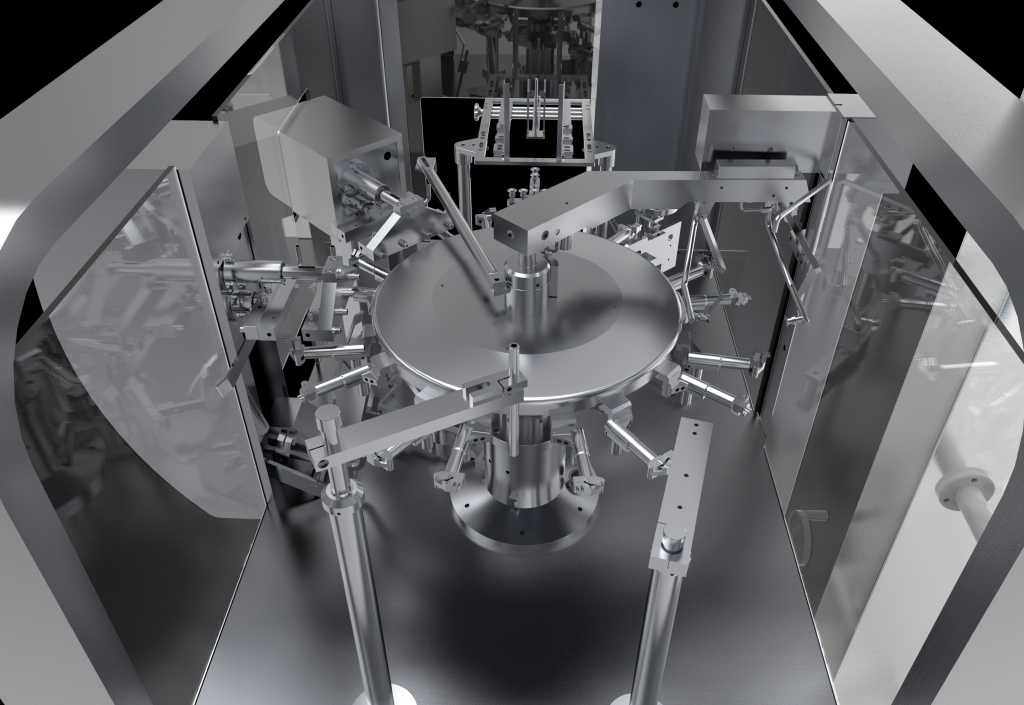

Packers and machinery manufacturers are paying more and more attention to the efficiency of machinery operation. The development of packaging machines also gradually tends to be flexible, efficient and multi-purpose. In addition, in order to save costs, manufacturers and packagers have begun to shift to a combination of machinery. In order to meet the expectations of consumers, a single packaging host will be equipped with different auxiliary machines. According to the characteristics of the packaged products, the appropriate coating will be selected on the part in contact with the product to achieve the ideal packaging line state. If you only pay attention to the main engine and ignore the choice of auxiliary equipment, the packaging main engine will not be able to exert the best packaging ability. This will also cause a certain amount of waste.

Automation

The development of packaging machines pays more and more attention to automation. The rapid development of the robotics industry can actually reveal the development trend of the mechanical packaging industry. Most industries are changing in the direction of liberating their hands and labor, which is also an inevitable trend in the development of the industry. On the packaging line, workers repeat the same work process, which will cause many problems over time. Automated machinery is also avoiding this situation, ensuring the efficiency of the production line and ensuring the safety of workers.

The competition between enterprises, the continuous innovation of machinery, the combination of emerging technologies and traditional machinery manufacturing, and other factors are urging the development of packaging machinery. The packaging machinery industry still maintains a lot of room for development. The cycle of innovation and replacement of packaging machinery has become shorter and shorter, making the requirements for packaging machines higher and higher. In other words, it is necessary to continuously improve the quality of the packaging machine, so that the packaging machine has good flexibility. Because only in this way, the development of packaging machines can meet the needs of market development.