Liquid filling machine is an automatic filling machine that can fill liquid such as water, wine, juice, ketchup, cream, honey, and other materials with certain fluidity into bottles or bags. This machine replaces the traditional manual filling method and reduces the input and use of labor. But at the same time, the maximum optimization of production time and benefits has been achieved. The formed liquid products we see in daily life all need to be filled through liquid packaging equipment.

For the classification of liquid filling equipment, we have many different standards.

The way materials are transferred from the storage bin to the packaging container often differs according to the characteristics of the materials. According to different principle of transmission driving force, we can simply divide the common liquid filling methods into the following:

Gravity filling

Gravity filling is to fill the material in the storage bin into the packaging container through the material’s own gravity.

Most common liquids have high fluidity, and widely used bottle packaging is one of the most common liquid packaging methods in daily life. The method of gravity filling does not have very strict requirements for the container, plastic bottles, glass bottles and other bottles can be used. Gravity filling is a good choice when the producer has a strong material flow. The filling material pipe extends into the bottom of the bottle to prevent liquid splashing and reduce waste. The filling quantitative error in the packaging container is small. Most of the bottled liquid beverages that we can see in our lives are filled by gravity.

The particularity and convenience of gravity filling make gravity filling the most common method of liquid filling. High precision, fast speed, meet the production requirements of larger output, can produce greater economic benefits.

Piston filling

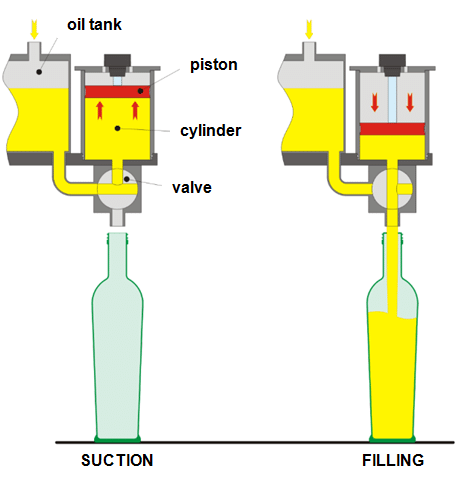

A simple understanding of piston filling, its principle is to use the method of increasing pressure to press the material into the package.

It is best to fill the material with the piston filling method with the liquid with slight viscosity and poor fluidity, such as ketchup, cake liquid, gel, etc. There are many types of piston filling machines, including automatic linear piston filling machines that can fill quickly and accurately, top piston filling machines, entry-level desktop piston filling machines, and other models. A variety of piston filling machines can meet the packaging of most light viscous liquids on the market.

The application of the piston filling machine solves the packaging of light viscous liquids. It is widely used in ketchup, thick sauces, and other sauces without granules. It is not limited by the shape of the filling container and is flexible in operation. It is especially suitable for liquid packaging which requires certain precision. The piston filling machine occupies a small area and is easy to operate. It is an entry-level model for liquid filling.

Pump filling

For highly viscous liquid materials such as honey, shampoo, face cream, etc., the material cannot be filled into the container by falling by its own gravity. Because of the high viscosity of the material itself, the filling speed of gravity filling and piston filling cannot achieve the desired effect. Therefore, it is necessary to rely more on the power provided by external machinery for filling.

Pump filling is one such filling method. Through the pump system used in the machinery, and then cooperate with the valve and other mechanical parts to achieve the purpose of conveying high-viscosity materials, and realize the packaging of such high-viscosity liquid materials.

For the filling form of liquid filling equipment, liquid filling machine can also be divided into linear filling and rotary filling, etc. Different classification criteria will produce different classification results. However, it still falls under the category of gravity filling, piston filling, and pump filling.

Refer:

https://www.researchgate.net/figure/olumetric-or-piston-filling-system_fig1_257548738